MG型定位螺旋式联轴器 MG-Setscrew Spiral Slit Type Flexible Coupling

|

特点:Features

一体成型的金属弹性联轴器。

One-piece metallic spring coupling.

适用较小力矩的轴联接,零回转间隙。

Suitable in small moment of force axis joint, Zero backlash.

弹性作用补偿径向、角向和轴向偏差。

Absorption of parallel, angular and shaft end-play misalignments.

顺、逆时针回转特性完全相同。

Identical clockwise and counter-clockwise rotational characteristics.

定位螺丝或夹紧螺丝。

Setscrew type or clamp type.

适用于步进电机、编码器。

Is suitable in Stepping Motor, enclder. |

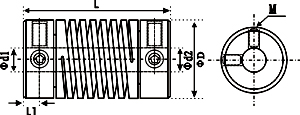

结构图:

|

|

选型指导:Ordering lnformation

|

例:MG–a280-10/14 MG:系列号,材料为铝合金

a280:a为定位型,280为外径尺寸28.6mm

10:d1轴径为10mm

14:d2轴径为14mm

n 请参考下图参数表

Example:MG–a280–10/14

MG: Series NO, Material: Aluminum Alloy

a280:a- Setscrew Type, Outside dimension 28.6mm

10:d1 Bore: 10mm

14: d2 Bore: 14mm |

MG型定位螺旋式联轴器尺寸表

MG- Setscrew Spiral Slit Type Flexible Coupling Dimensions

|

MG型号

MG Model |

d1-d2范围

d1-d2 Bore Scope |

尺寸

Dimensions (mm) |

固定螺丝

Clamp Screw | |||

|

D |

L |

L1 |

M |

拧紧力矩

Wrench Torque (N.m) | ||

|

MG-a150-d1/d2 |

3 4 5 |

15.5 |

23.0 |

2.5 |

M3 |

1.0 |

|

MG-a170-d1/d2 |

4 5 6 |

17.5 |

23.0 |

2.5 |

M3 |

1.0 |

|

MG-a190S-d1/d2 |

5 6 6.35 8 |

19.5 |

19.1 |

2.5 |

M4 |

0.7 |

|

MG-a190-d1/d2 |

5 6 6.35 8 |

19.5 |

24.5 |

2.5 |

M4 |

2.0 |

|

MG-a250-d1/d2 |

5 6 6.35 8 10 |

25.4 |

25.4 |

3.5 |

M4 |

1.7 |

|

MG-a280-d1/d2 |

6 8 9.525 10 12 12.7 |

28.6 |

28.6 |

3.7 |

M5 |

1.7 |

|

MG-a380-d1/d2 |

8 10 12 12.7 14 15 |

38.1 |

38.1 |

4.3 |

M5 |

3.8 |

|

MG-a500-d1/d2 |

12 12.7 14 16 18 19 |

50.8 |

50.8 |

5.5 |

M6 |

4.0 |

备注:内孔在d2范围内均可做。

MG- Setscrew Spiral Slit Type Flexible Coupling Technical Data

|

MF型号 MF Model |

扭矩Torque |

纠偏值

Perm. displacements |

扭矩刚性

Torsional Stiffness

(N.m / rad) |

最高转速

Max.speed

(rpm) |

惯性力矩

Moment of Inertia

(kg.m2) |

重量

Weight

(g) | |||

|

额定Rated

(N.m) |

最大Max

(N.m) |

角向

Angular

( °) |

轴向

Axial

(mm) |

径向

Parallel

(mm) | |||||

|

MG-a150-d1/d2 |

0.2 |

0.4 |

2.0 |

±0.15 |

0.1 |

35 |

10000 |

3.0×10-7 |

10 |

|

MG-a170-d1/d2 |

0.3 |

0.6 |

2.0 |

±0.15 |

0.1 |

65 |

10000 |

4.5×10-7 |

12 |

|

MG-a190S-d1/d2 |

0.4 |

0.8 |

2.0 |

±0.15 |

0.1 |

105 |

10000 |

5.6×10-7 |

13 |

|

MG-a190-d1/d2 |

0.4 |

0.8 |

2.0 |

±0.15 |

0.1 |

95 |

10000 |

6.2×10-7 |

14 |

|

MG-a250-d1/d2 |

1.2 |

2.4 |

2.0 |

±0.15 |

0.1 |

165 |

10000 |

2.6×10-6 |

26 |

|

MG-a280-d1/d2 |

1.6 |

3.2 |

2.0 |

±0.15 |

0.1 |

265 |

8000 |

7.0×10-6 |

42 |

|

MG-a380-d1/d2 |

4.2 |

8.8 |

2.0 |

±0.15 |

0.1 |

340 |

8000 |

3.0×10-5 |

76 |

|

MG-a500-d1/d2 |

9.0 |

18.0 |

2.0 |

±0.15 |

0.1 |

560 |

6000 |

9.0×10-5 |

255 |

说明:Explanation:

特殊孔径和键槽可按需求加工,请与我们联系. Bore and keyway modifications are available on request, Please take advantage of our bore modification services.